Top Features to Look for When Purchasing Industrial Scales for Your Facility

Top Features to Look for When Purchasing Industrial Scales for Your Facility

Blog Article

Why to Pick Industrial Scales for Accurate Weight Measurement in Various Industries

In an age where precision is critical, the selection of industrial ranges for exact weight measurement plays a crucial role across diverse markets. These scales not just boost functional efficiency yet additionally make certain conformity with governing standards, affecting whatever from production to delivery. Their robust layout and advanced innovation provide to numerous applications, enhancing the requirement for thorough weight administration. Recognizing the subtleties of these ranges is important for any type of company intending to maximize procedures and mitigate costly errors. Yet, the inquiry remains: what certain elements should one think about when picking the right scale for their special operational requirements?

Importance of Accurate Weight Dimension

In the realm of industrial procedures, the significance of accurate weight dimension can not be overemphasized. Exact weight measurement is fundamental throughout numerous markets, influencing both functional performance and product quality - Industrial Scales. It works as a critical factor in inventory monitoring, guaranteeing that materials are adequately accounted for, therefore minimizing waste and minimizing expenses

In manufacturing, accurate weight dimension directly influences manufacturing processes. Anomalies in weight can result in second-rate items or excessive resource allotment, influencing overall productivity. Additionally, in markets such as pharmaceuticals and food production, adherence to rigorous weight specifications is important for governing conformity and consumer safety.

Furthermore, accurate weight measurements assist in efficient logistics and supply chain administration. Properly weighed shipments ensure that transportation expenses are maximized which stock degrees are preserved properly, consequently protecting against supply scarcities or overstock circumstances.

Sorts Of Industrial Scales

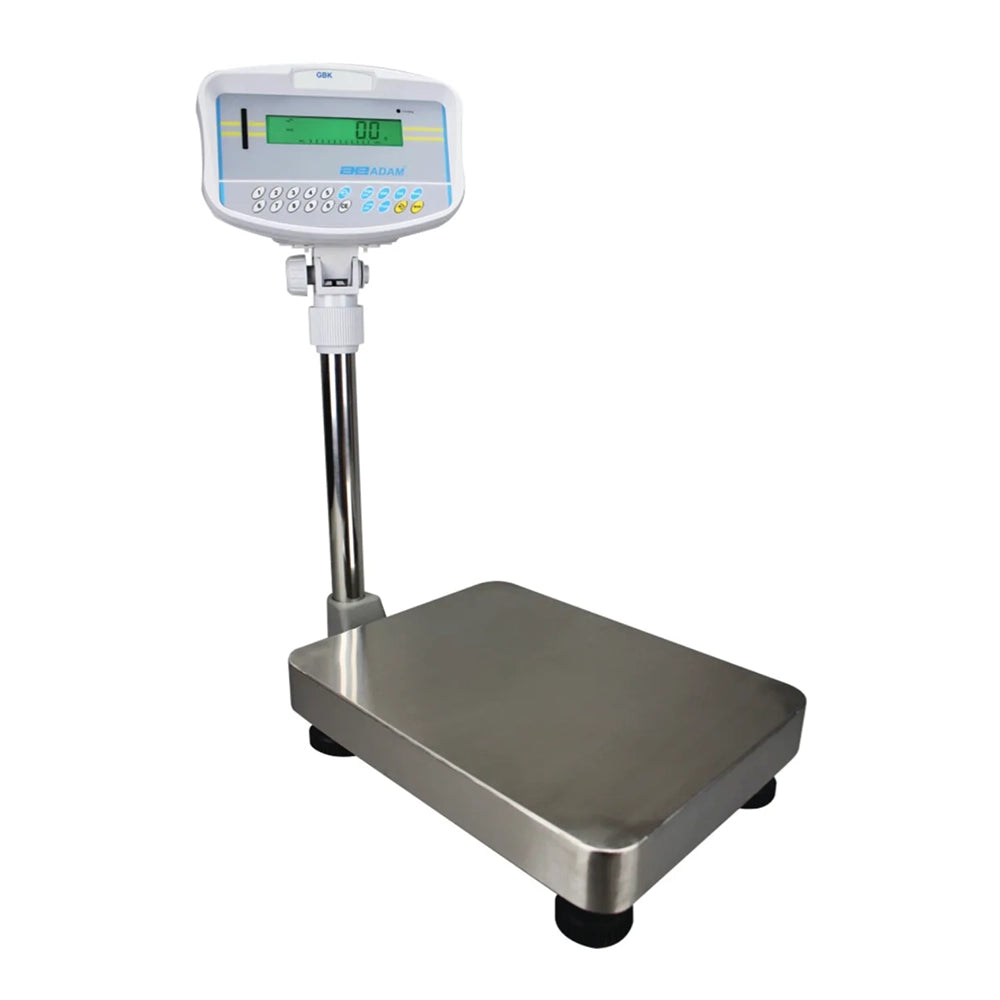

A wide array of industrial scales are readily available, each created to meet certain measurement requires across varied markets. Common kinds consist of floor ranges, which are robust and appropriate for considering large items or pallets in storehouses and warehouse. Bench ranges are smaller sized and optimal for lighter products, commonly made use of in retail setups or manufacturing for exact section control.

Another classification is portable scales, which provide the versatility to be moved conveniently around job sites, making them suitable for field procedures or temporary setups. Precision ranges, on the various other hand, are made for high accuracy and are frequently used in research laboratories and quality control atmospheres.

Tons cells are essential components in different commercial scales, converting push into an electric signal for exact analyses. In addition, vehicle ranges give the methods to evaluate heavy lorries and their loads, making sure conformity with guidelines and enhancing logistics.

Finally, checkweighers automatically compare the weight of products against preset limits, enhancing quality assurance in production lines (Industrial Scales). Each type of commercial range offers an one-of-a-kind function, catering to the details demands of industries such as manufacturing, logistics, food processing, and drugs

Advantages of Utilizing Industrial Scales

Continually making use of commercial ranges offers substantial benefits across numerous fields. Among the key advantages is boosted accuracy in weight measurement, which is crucial for keeping top quality requirements and regulative compliance. Exact measurements avoid pricey mistakes in shipping, stock, and production monitoring, eventually find here leading to boosted visit the site operational performance.

Additionally, industrial ranges are developed for sturdiness and robustness, permitting them to endure harsh settings usually located in manufacturing and warehousing. This resilience makes sure a long life-span, minimizing the need for regular replacements and maintenance prices.

Moreover, employing industrial scales enhances safety and security and decreases waste. By making certain that items are considered properly, business can prevent straining lorries, which can bring about accidents and fines.

Applications Across Numerous Industries

Industrial scales play a pivotal duty in numerous fields, consisting of production, logistics, food processing, and drugs. In production, these ranges are crucial for ensuring that basic materials are determined accurately, thereby keeping item high quality and consistency (Industrial Scales). Accuracy in weight measurement directly influences manufacturing effectiveness and price management

In logistics, commercial ranges help with the accurate considering of shipments, which is essential for adhering to maximizing and delivering laws products prices. Accurate weight data aids simplify operations and boosts supply chain administration.

The food processing market counts greatly on industrial scales for conformity with health and wellness policies. They are used to weigh components precisely, making sure that solutions fulfill both top quality standards and lawful needs. This is essential not only for customer safety and security however additionally for keeping brand honesty.

Pharmaceutical firms use industrial scales to ensure precise dosages in drug production, where also the tiniest inconsistency can have significant consequences. Conformity with rigorous regulative standards makes precise weight measurement essential in this field.

When Choosing Ranges,## Aspects to Take Into Consideration.

Selecting the right range for details applications needs careful consideration of a number of factors. First and foremost, the capability of the range is important; it has to fit the optimum weight of the products being determined without exceeding its restrictions. Furthermore, the readability, or smallest increment the range can accurately show, is vital for accuracy, specifically in markets where weight discrepancies can lead to significant economic losses or safety and security concerns.

Ecological conditions additionally play a substantial function in scale option. For example, scales used in damp or corrosive settings may call for customized materials to guarantee toughness. In a similar way, portability might be essential in certain applications, requiring lightweight and battery-operated designs.

Verdict

In verdict, the selection of industrial scales is pivotal for guaranteeing accurate weight dimension throughout varied industries. Therefore, investing in high-quality industrial scales is essential for companies aiming to keep high standards and take full advantage of earnings.

Report this page